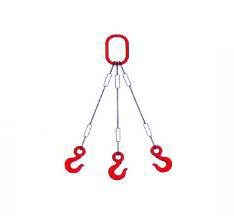

Common Combinations Of Wire Rope Slings

Product Details

1. Overview of wire rope slings

Wire rope slings are processed from steel wire ropes. The ropes mainly used for hoisting, traction, tensioning and load-bearing are called steel slings. Wire rope sling has the characteristics of high strength, light weight, stable work, and not easy to break the whole root suddenly. It is widely used in steel, chemical, transportation, port and other industries.

2. Commonly used combinations of wire rope slings

Single-leg rigging: This rigging can be used as a single-limb lashing rigging. When a single-limb lashing rigging is used, you only need to hook the hook into the chain. At this time, the rated load will be reduced by 20%.

Two-leg rigging: This rigging can be used as a two-limb binding rigging. When the two-limb binding rigging is used, only the hook needs to be hooked into the chain, and the rated load will be reduced by 20%.

Three-legged rigging safety guarantee: 4 times the safety factor. Surface treatment: polishing, blackening, galvanizing, spray painting, etc.

Three, the wire rope sling is divided into 8 types

1. Pressed steel wire rope sling (fiber core FC)

2. Pressed steel wire rope rigging (steel core IWRC)

3. Insert braided steel wire rope sling (fiber core FC)

4. Insert braided wire rope rigging (steel core IWRC)

5. Pressed steel cable and wire rope sling

6. Insert braided steel cable wire rope set rigging

7. No joint rope loop (fiber core FC)

8. No joint rope loop (steel core IWRC)

Fourth, the use of wire rope slings

1 Galvanized steel wire rope can be used as raw material for steel wire rope sling in wet or open environment to enhance the anti-rust performance.

2 In addition to the wear of the outer layer of the steel wire rope, the wire sling is mainly broken due to metal fatigue caused by repeated bending when bypassing the hook and the suspended object. Therefore, the ratio of the hook or the suspended object to the diameter of the wire rope determines the service life of the wire sling Important factor. 3 When the degree of wear and corrosion of the surface layer of the steel wire rope sling exceeds the specified value, it shall be scrapped.

4 The wire rope sling is mainly used in the transportation that requires high-strength ropes such as lifting and pulling. It is strictly forbidden to stand under the suspended object or pass on the object during use.

5. Scrap standard of wire rope sling

1 The overall design of the hoisting machinery does not allow the wire rope sleeve to have an infinite life.

2 When there are broken wires at or near the end of the wire rope sleeve, even a small number indicates that the stress in this part is very high, which may be caused by incorrect installation of the rope end. The cause of the damage should be found out. If the rope length allows, cut off the broken wire and reinstall it reasonably.

3 If the broken wires are close together to form a local aggregation, the wire rope sleeve should be scrapped. If such broken wires are gathered in the rope length range of less than 6d, or concentrated in any strand, then even if the number of broken wires is less than the value listed in the table, the wire rope sleeve should be scrapped.

4 In some occasions, fatigue is the main cause of damage to the wire rope sling. Broken wires only begin to appear after a period of use, but the number of broken wires gradually increases, and the time interval becomes shorter and shorter. In this case, in order to determine the increase rate of broken wires, carefully inspect and record the increase of broken wires. Identifying this "rule" can be used to determine the date of future scrapping of wire rope slings.

5 If the entire rope strand is broken, the wire rope sling should be scrapped.

6 When the fiber core of the steel wire rope sling is damaged or the steel core (or the inner strands in the multilayer structure) is broken and the rope diameter is significantly reduced, the steel wire rope sling should be scrapped.

6. Precautions for purchasing steel wire rope slings

1 Is DIN, manufacturer's name and CE mark printed on the pressure sleeve?

2 Is the suppression correct?

3 Is the end of the suppressed wire rope compressed by the compression sleeve to expose the 0.5d diameter of the steel rope? 4 Can the end of the suppressed wire rope be seen through the control hole?

5 Is the wire rope straight when laid flat?

6 Is the diameter of the wire rope accurate?

7 Is the length of the compression sleeve 4.5×d? Try to choose well-known brands

Seven, introduction to manufacturers of commonly used combinations of wire rope slings

We are a professional manufacturer integrating research, development, and production. The main products include various specifications and models of wire rope, wire rope sling, nylon rope sling, special fiber flexible sling series, flat sling series, safety net series, Safety belt series, lifting chain series, beam spreader series, metallurgical fixture series and three-action tool series. Products are widely used in metallurgy, machinery, railways, petrochemicals, ports, electric power, automobiles, aviation, construction and other fields.