Product Details

https://www.lycrafilter.com/PP-Melt-Blown-Non-woven-Fabric-Machine.html

The PP meltblown nonwoven fabric machine is designed to run automatically for 24 hours.

Its professional electrostatic equipment adds positive charge to the fabric to ensure that the meltblown fabric filters BFE99.

Screw compressor: Supply high air pressure,to spray liquid pp into fiber

Air heater: To heat air into 250 degree.Inside tunnel use S way.Max heating efficiency

Extruder: Melt polypropylene material into liquid,and mixing pp more equally.Has two mixer part inside,to extrude pp material regular and high melt blown rate

Filter equipment: Our own design this filter install between extruder and mold.Filtering polypropylene material inside dust,particulate...let machine running long time no stop.And every time clean filter only 1 minute

Mold: Liquid pp into mold.With hot pressure air to spray mold holes,Mold will spray much micron fibers

Receiver: flexible Belt webbing,Fiber sprayed into belt and into fabric,Inside exhaust cooling fans.To cool belt and and fabric cool down quickly.Improve fabric density

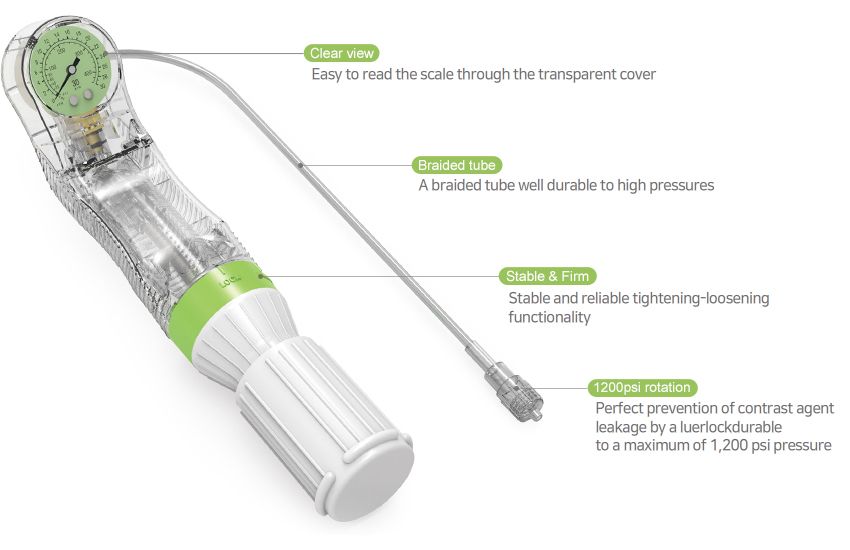

Electrostatic equipment: Generator will create positive charge.And fabric filed with high strong electric.Much positive charge will absorbent into fabric inside.So let fabric has high filtration

Winder: Winding fabric into a roll.And Slitting system will cut fabric into small width,Like 3ply mask 175mm and N95 Mask 260mm both adjustable.

Oven: heat 400 degree for carbonize mold holes inside pp wastage.This equipment normally 15 days running one time.

Contact us on: songyanweichange@163.com