Small Scales Toilet Paper Making Machine

Product Details

I:Technical Parameter :

1.Raw material: white waste paper edge

2.Output paper:toilet paper ,napkin paper ,facial paper

3.Output paper weight:15~35g/㎡

4.Capacity:5T/D

5.Net paper width:2000mm

6.Wire width:2300mm

7.Working speed:50-120m/min

8.Design speed:150m/min

9.Rail gauge:2800mm

10.Drive way: Alternating current frequency conversion adjustable speed ,section drive .

II:The structure and specifications of main equipment

(1) Cylinder mold part :

φ1500mmx2300mmx2800mm stainless steel plate cylinder mold 1 pc ,

φ450mmx2300mmx2800mm couch roll 1 pcs,rubber shore hardness 38℃±2.

(2) Dryer part :

φ2500mmx2300mmx2800mm alloy dryer 1 pcs ,φ550mmx2300mmx2800mm touch roll 1 pcs ,rubber shore hardness 92℃±2,pneumatic loading device ,equipped with double layer warm keeping type dryer hood,φ600mm axial-flow ventilator 1 set.

(3) Winding part :

φ600mmx2300mmx2800mm winding cylinder 1pcs , independent drive ,model JZQ250 reduction gears 1 set .

(4) Rewinding part :

1880mm rewinding and perforating machine 1 set, paper cutting machine 1 set .

NO.

Item & function

1

Ф1500mmx2300mmx2800mm

Stainless steel cylinder mold

Provide the pulp fiber to the paper making felt through rotating in the cylinder mold box .

2

Ф450mmx2300mmx2800mm Couch roll

Overhead the cylinder mold ,give a pressure to the felt and cylinder mold ,to make pulp fiber attached in the paper making felt surface .

3

Cylinder vat

There is no pulp vestige ,no spilling .This make paper even and have strength of landscape orientation and portrait .

4

Φ550mmx2300mmx2800mm Touch roll

Under the dryer can ,give pressure to the dryer can ,to achieve the tight touch between paper and dryer .

FAQ

1.What information do you need,if i need to get a quotation from you? Answer:Output paper type;Capacity(tons/24hours);Output paper weight(gram/m2);Raw material.

2.How long is guarantee period for paper making machine? Answer:12 months after formal operational

3.What is the delivery time if we make a order from you? Answer:Usually,the delivery time for smaller machines is 30-45 days after receiving deposit,but for bigger machines,it will be longer to make sure the equipment quality.

4.What is your payment terms?

Answer:(1). T/T(telegraphic transfer)30% as deposit,and 70%balance paid before shipment.

(2) . 30%T/T + 70%L/C at sight.

(3) (3). 100%L/C at sight.

5.How is the quality of your equipment?

Answer:(1).We have been specializing in pulp and paper making machines for 40 years.We have enough practice/experience.To keep and develop our good reputation,we couldn't allow the unqualified machine,as well as you.

(2).We have a technician team of engineers and experts.They mainly research the advanced paper making

technology,to make sure our machines’ design are newest.

(3). The machines will be pre-installed at workshop before delivery.

6.Why your price is higher than other similar supplier?

Answer:Different quality,different price.Our price is matched with our high quality.Compared with other suppliers based on the same quality,our price is lower.But anyway,to show our sincerity,we will give you some discount.

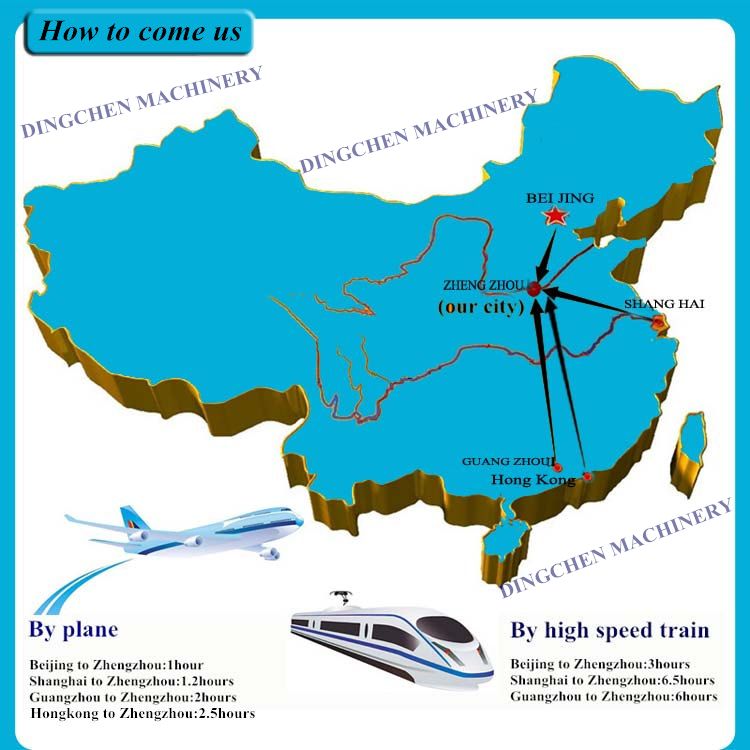

7.Can we visit your factory and the running machine has installed in China ?

Answer:Welcome to visit our factory .You can check our production ability ,processing ability ,check our facilities and running paper production line .What is more , you can discuss with engineers directly ,and learn the machines well .

1.Pre-sales Service

Offering comprehensive technical and business consultation services;

Proposing the most suitable scheme and equipment for our clients;

Designing and fabricating targeted products according to the special re quirements of clients;

Training periodically high qualified service technician.

2.After-sales Service

Highly inspecting equipments in every working procedure, quality come s first;

Fast & Safe Delivery;

Assisting our clients for foundation construction of equipments;

Dispatching engineers to install and debug equipments;

Training the first-line operators on site;

Regularly visit clients to solve production problems;

Providing life-long maintenance service;

Providing technical exchanging;

Warmly welcome for your visiting !!! Please contact Lisa ~~~ Tel/Whatapp/Wechat:008613674911285

.jpg)