Product Details

Screw compressor: Supply high air pressure,to spray liquid pp into fiber

Air heater: To heat air into 250 degree.Inside tunnel use S way.Max heating efficiency

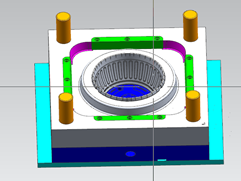

Extruder:Melt polypropylene material into liquid,and mixing pp more equally.Has two mixer part inside,to extrude pp material regular and high melt blown rate Filter equipment: Our own design this filter install between extruder and mold.Filtering polypropylene material inside dust,particulate...let machine running long time no stop.And every time clean filter only 1 minute Mold: Liquid pp into mold.With hot pressure air to spray mold holes,Mold will spray much micron fibers Receiver: flexible Belt webbing,Fiber sprayed into belt and into fabric,Inside exhaust cooling fans.To cool belt and and fabric cool down quickly.Improve fabric density Electrostatic equipment:Generator will create positive charge.And fabric filed with high strong electric.Much positive charge will absorbent into fabric inside.So let fabric has high filtration Winder: Winding fabric into a roll.And Slitting system will cut fabric into small width,Like 3ply mask 175mm and N95 Mask 260mm both adjustable. Oven: heat 400 degree for carbonize mold holes inside pp wastage.This equipment normally 15 days running one time.